Intelligent Cost Estimator ( ICE ) Software

ICE – Intelligent Cost Estimator proudly proclaims to be India’s 1st comprehensive zero base costing software. A tool par excellence in the field of cost management , it facilitates cost calculation of a part & articulately keeps the cost records for future reference.

ICE is designed to cover all the cost drivers and their impact for cost calculation. Software simulates the factory environment for processing the raw material to finished part or an assembly. ICE aptly furnishes otherwise time consuming reports in seconds viz. Only RM Impact report , RM Change History , Part Price Calculation history , Current Commodity base prices , Commodity category wise Spend analysis in an assy. Easy traceability & enhanced transparency make ICE “Simply Effective”.

For Whom Persons responsible for Product Cost Management

- Automotive OEM’s

- Auto Component Manufacturers

- Engineering OEM’s

- Home Appliances Manufacturers

- Electrical Equipment Manufacturers

- Earthmoving & Agricultural Machinery

Benefits Why Target Price Analysis Software

- Should cost analysis for optimum cost

- Scientific coverage of all cost factors

- Enhanced Transparency

- System based approach

- Easy traceability & Analytics

- Standardization of cost data

- Sound base for Internal Audits

Why Us

- Software motto- “Simply Effective”

- Developed by Professional domain experts

- Tested & validated by Industry experts

- Built-in Analytics to see broader perspective

- Easy to use & interpret

- Practical aspects in focus

- Software design diligence

- Strong focus on systems & standardization

- De-skilling the cost estimation work

- Real value for investment

Commodity Categories

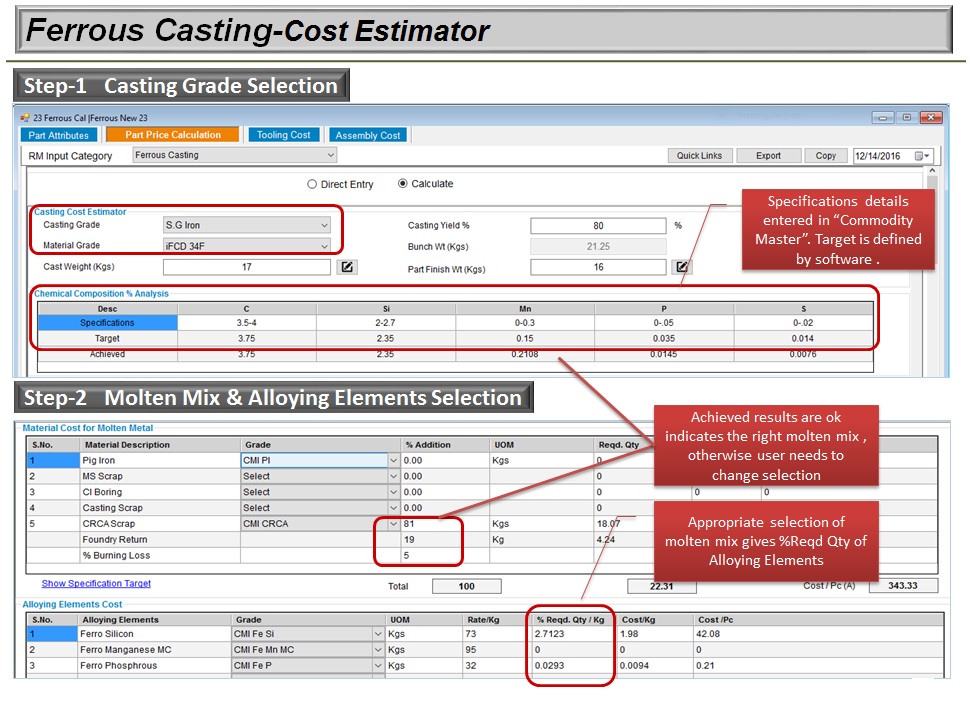

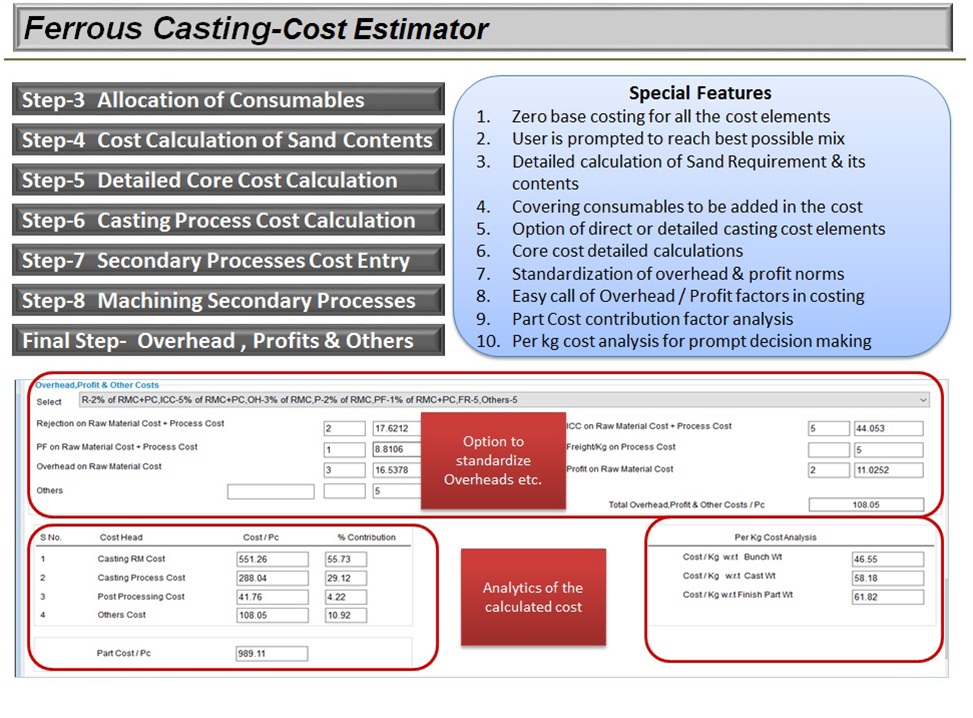

Ferrous Casting

Non-Ferrous Casting

Sheet Metal & Fabrication

Machining

Extrusion Rubber & Plastic

Forging

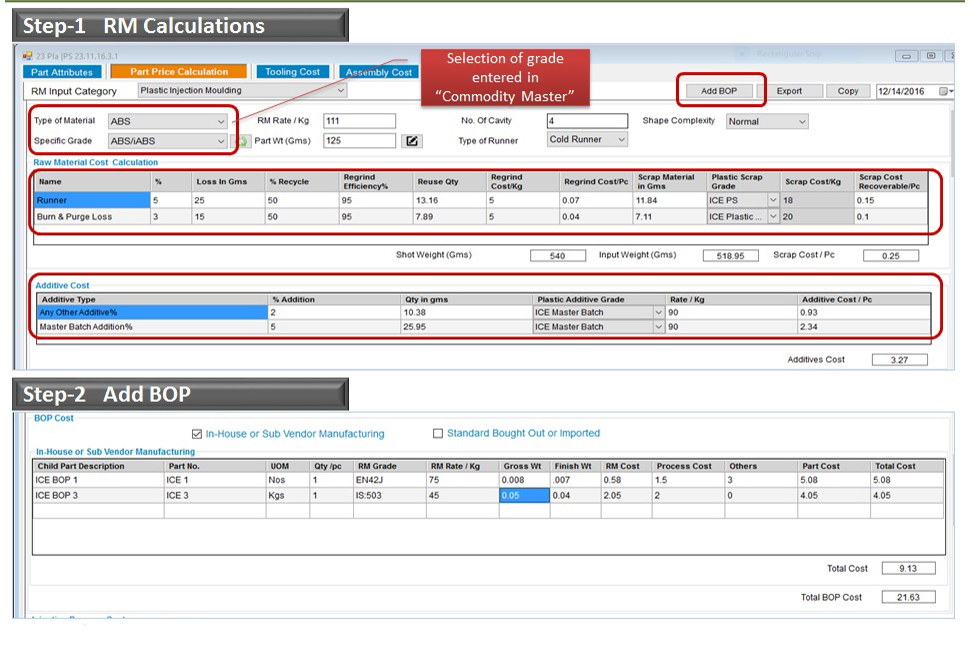

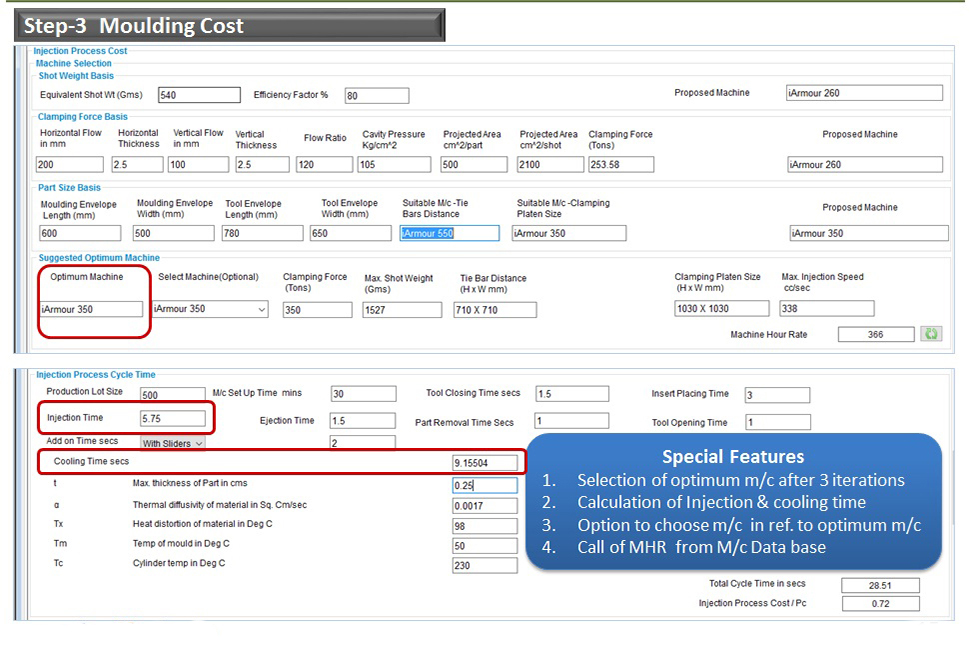

Plastics Injection Moulding

Rubber Injection Moulding

Wiring Harness Assemblies

Pipes & Tubes Bending

Processes Covered

Software comes with an option to add secondary standard processes directly.

Masters & Reports

Masters

- 1Commodity

- 3Production Site

- 5Shift Model

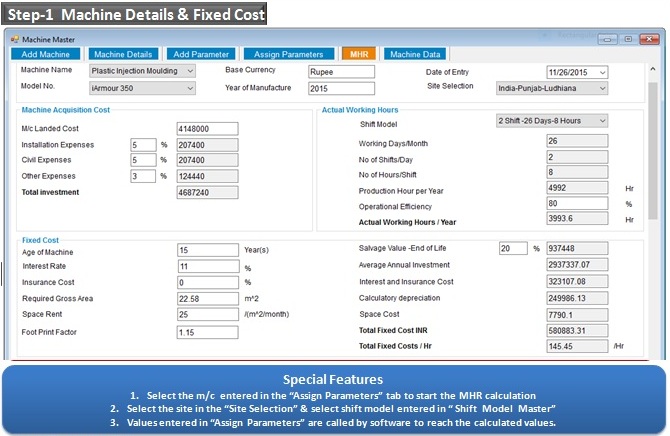

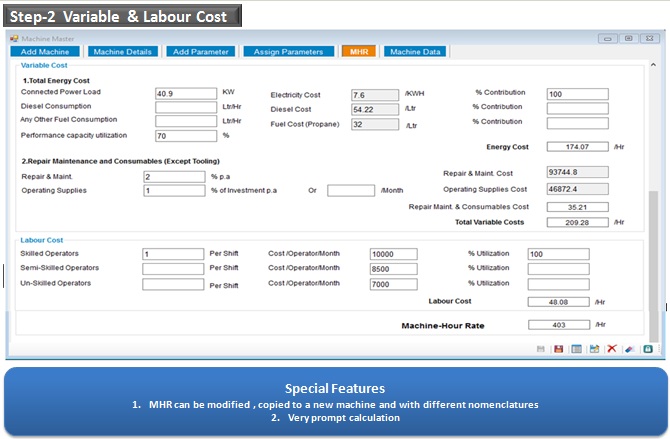

- 7Machine

- 9Tool

- 11Process

- 13BOP

- 2Overhead/Profit

- 4Taxes

- 6UOM

- 8Supplier

- 10Customer

- 12Currency

- 14Product Model

Reports

Target vs. Estimated Cost

Only RM Cost Change Impact

Commodity Wise Spend Analysis

RM Price History

Site History

Cost History

Purchase Proposals

RFQ Manager

Other Features

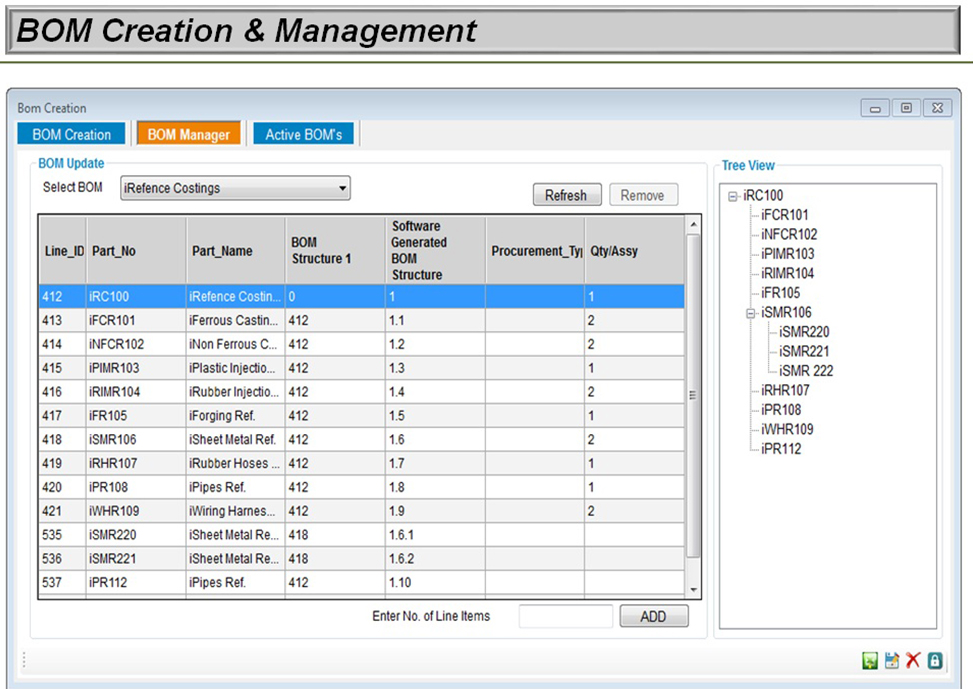

Bill of Material Creation

Widgets & Resource Center